The Role of an Optical Fibre Diameter Analyser in Quality Control

The Role of an Optical Fibre Diameter Analyser in Quality Control

Blog Article

Achieve Superior Lead To Fiber Optics With a Reputable Size Analyser

In the realm of fibre optics, accomplishing exceptional results is basically connected to the accuracy of diameter dimensions. A reputable size analyser acts as a crucial tool, ensuring that also minute variations in fiber diameter are found and addressed, thereby guarding signal stability and light transmission performance. The relevance of these measurements extends past simple conformity; they are pivotal in boosting production processes and promoting rely on end-user applications. As we discover the complexities of choosing an ideal size analyser, the ramifications for total performance and sector criteria warrant closer exam.

Relevance of Diameter Measurement

Precisely gauging the size of fiber optics is crucial for making certain optimum efficiency and reliability in telecommunications. The diameter directly influences the light transmission attributes of fibre optic wires, influencing bandwidth, signal honesty, and total data transmission effectiveness. Variants in size can result in raised attenuation and diffusion, which can weaken signal quality and limit the reliable array of interaction systems.

Furthermore, conformity with sector standards requires precise size dimensions to make sure compatibility with connectors and splicing techniques. Mismatched sizes can result in increased insertion loss and connector imbalance, causing prospective system failings. Furthermore, the production process of fibre optics needs strict top quality control measures, where size measurements function as an essential criterion for evaluating item uniformity and performance.

In high-stakes environments such as information facilities and telecommunication networks, the significance of diameter dimension transcends simple conformity; it is indispensable to maintaining system integrity and efficiency - optical fibre diameter analyser. Thus, spending in precise fiber optics size analysers is essential for suppliers and service providers aiming to maintain the highest requirements in telecoms infrastructure. Appropriate measurement strategies can considerably enhance the functional effectiveness of fibre optic networks, inevitably impacting customer experience and solution shipment

Functions of a Quality Analyser

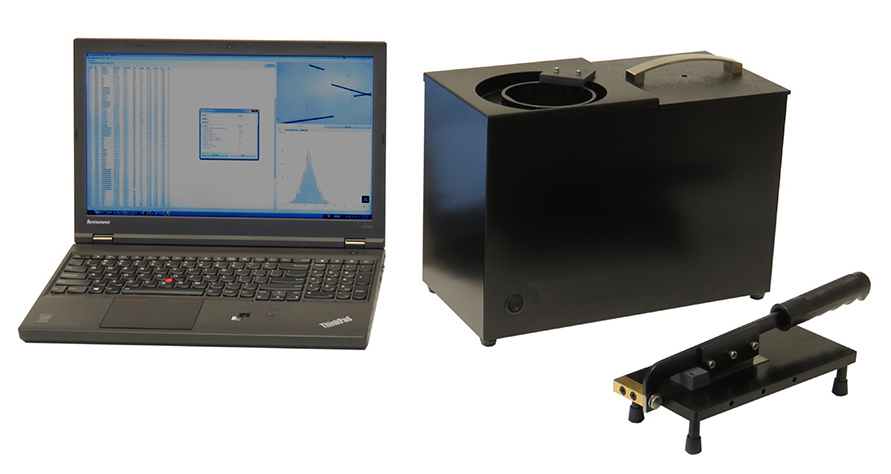

A high quality fiber optics diameter analyser is characterized by several crucial features that enhance its functionality and reliability in gauging optical fiber diameters. First and leading, precision is paramount; high-resolution dimension abilities guarantee that even the slightest variants in size are precisely identified. This is commonly promoted by advanced optical sensors and calibration methods that reduce measurement error.

An additional essential attribute is straightforward software that allows operators to conveniently translate and analyze information. Instinctive user interfaces make it possible for fast changes and settings adjustments, streamlining the measurement process. Additionally, lots of analysers come outfitted with information logging and reporting features, giving essential insights for quality assurance and conformity.

Longevity is also vital, as fiber optic environments can be extreme. A durable design, usually including safety casings and weather-resistant components, makes certain dependable procedure under differing conditions. Moreover, compatibility with various fibre types and dimensions expands the analyser's convenience, making it appropriate for different applications.

Advantages of Accurate Dimensions

Furthermore, precise size analysis plays a critical duty in quality assurance more throughout the production process. By making certain that fibre optic cords meet specified size resistances, producers can reduce the risk of issues, which can cause expensive failures or downtimes in telecoms systems. This dependability promotes self-confidence among end-users and customers, as they can trust the performance of the installed systems.

In addition, exact size dimensions help with far better compatibility with adapters and various other parts in the fiber optic community. This compatibility is crucial for seamless combination and optimum performance, eventually resulting in reduced installment time and costs. optical fibre diameter analyser. In summary, accurate diameter dimensions in fibre optics not just enhance efficiency and dependability but also add to better standards and boosted client satisfaction in the affordable telecom market

Effect on Manufacturing Efficiency

In the realm of fiber optics producing, the precision of size measurements straight affects manufacturing efficiency. Accurate diameter evaluation guarantees that the optical fibers created meet rigorous specs, reducing the likelihood of defects that could bring about pricey rework or scrap. When producers execute trusted size analysers, they can identify discrepancies in real-time, allowing for immediate changes to manufacturing processes. This positive strategy lowers downtime and boosts overall throughput.

Additionally, consistency in diameter dimensions promotes harmony in the end product, which is critical for preserving premium requirements. Irregular sizes can impact the performance of fiber optic cords, leading to increased signal loss or degradation with time. By making certain specific measurements, makers can boost product reliability, eventually enhancing customer contentment and reducing service warranty insurance claims.

Buying innovative diameter analysers also improves the high quality control process. Automated data collection and evaluation assist in quick decision-making and supply understandings into production patterns, even more enhancing operational effectiveness. In summary, the impact of exact diameter dimensions on producing effectiveness is profound, as it not only enhances production however additionally enhances item quality and dependability in the affordable fibre optics market.

Choosing the Right Size Analyser

Choosing the proper size analyser is essential for maintaining the high standards developed in fiber optics making. The appropriate analyser makes certain accurate dimension of optical fiber diameters, which is critical for achieving ideal efficiency and reliability in last items.

When choosing a size analyser, consider vital specifications such as dimension resolution, precision, and array. An analyser with a wide dimension variety can fit numerous fiber kinds, while high precision and resolution are crucial for discovering also minor diameter variants that can influence efficiency.

Furthermore, examine the innovation used in the analyser. Optical and laser-based analysers frequently offer superior accuracy compared to typical call methods. Search for functions such as real-time information handling, easy to use user interfaces, and compatibility with existing production systems to boost operational efficiency.

In addition, take into consideration the websites assistance and service provided by the producer. A dependable vendor will certainly offer thorough training, maintenance, and technical assistance, making sure that your team is equipped to use the analyser properly.

Eventually, investing in the ideal size analyser will check out this site not just simplify production processes but additionally guarantee the distribution of top quality fiber optic products to the market. (optical fibre diameter analyser)

Conclusion

In conclusion, the combination of a reputable diameter analyser is crucial for attaining exceptional results in fibre optics. Precise diameter measurements play an important role in ensuring ideal light transmission, lessening issues, and improving compatibility with adapters.

A dependable size analyser offers as an essential tool, making certain that even minute variations in fibre diameter are detected and resolved, thus protecting signal stability and light transmission effectiveness. Thus, spending in precise fiber optics diameter analysers is crucial for makers and service companies aiming to maintain the highest possible standards in telecoms framework.A high quality fiber optics diameter analyser is defined by numerous key features that improve its functionality and reliability in measuring optical fiber sizes. In summary, exact diameter dimensions in fibre optics not just enhance efficiency and dependability yet additionally contribute to greater quality requirements and enhanced consumer complete satisfaction in the affordable telecom market.

Report this page